When it comes to custom and personalized clothing, two printing methods dominate the conversation: DTG (Direct-to-Garment) printing and DTF (Direct-to-Film) printing. Both offer incredible possibilities for designers, small businesses, and hobbyists, but knowing which method suits your needs can be tricky.

In this blog, we’ll break down what DTG and DTF are, compare them side by side, discuss their differences, debunk common misconceptions, LOGEQI’s DTF T-shirts, and help you decide which method works best for you.

Whether you’re a small business owner, a hobbyist, or just curious about the latest in apparel printing technology, our blog will give you a clear picture of what to expect. Discover now!

What is DTG Printing?

Direct-to-Garment (DTG) printing is a popular method for creating high-quality, detailed designs directly on fabric. Using specialized inkjet printers, DTG applies water-based inks that soak into the garment’s fibers, producing soft, breathable prints that feel like part of the fabric rather than sitting on top.

DTG works like a regular printer but is designed for textiles, allowing for intricate designs, smooth gradients, and a wide range of colors without the need for screens or stencils. Pre-treatment is often required, especially for dark or cotton garments, to ensure vibrant colors and proper ink adhesion. After printing, the garment is heat-cured to make the design durable and washable.

This method is ideal for small runs, custom orders, and detailed designs. While excellent for cotton and cotton blends, DTG is less efficient for large-scale production or synthetic fabrics and requires careful printer maintenance.

What is DTF Printing?

Direct-to-Film (DTF) printing is a newer method for creating vibrant, durable designs on apparel. Unlike DTG, DTF prints designs onto a special transfer film using pigment-based inks. The design is then coated with a powder adhesive, heat-cured, and later transferred onto the garment with a heat press.

One of DTF’s biggest advantages is versatility. It works on almost any fabric, cotton, polyester, blends, nylon, and dark garments, without extensive pre-treatment. The prints are highly durable, retain color vibrancy, and resist washing over time.

DTF also offers production flexibility. Designs can be printed on film in advance, making it easy to stock transfers and handle batch orders efficiently.

Maintenance is simpler compared to DTG, as DTF printers are less prone to clogging. While the print sits slightly on top of the fabric and may feel less soft than DTG, modern adhesives make DTF prints flexible, wearable, and long-lasting.

DTF vs DTG: What’s the Difference?

1. Print Quality & Detail

DTG printing excels in producing highly detailed designs and gradients. Because the ink is absorbed directly into the fibers, you can achieve fine lines, photo-quality images, and complex color blends.

In comparison, DTF prints are also capable of excellent detail, but because the design is transferred from a film, ultra-fine textures may sometimes appear slightly less sharp than DTG, particularly on very dark fabrics.

2. Fabric Compatibility

DTG works best on cotton or high-cotton blends. It struggles with polyester or synthetic materials without special pre-treatment.

On the other hand, DTF is extremely versatile, performing well on cotton, polyester, blends, and even specialty fabrics. This makes DTF a better choice for a wider range of apparel options.

3. Color Vibrancy

DTG can produce vivid colors, especially on light garments, but dark fabrics require pre-treatment for color brightness.

DTF prints are generally brighter and more consistent across different fabric colors, including dark garments, because the transfer layer ensures the colors pop.

4. Design Complexity Handling

Both methods can handle complex designs, but DTG is slightly better for photorealistic prints with subtle shading. DTF excels with bold, multi-color designs and can be layered or stacked for unique effects.

5. Feel of Print

DTG prints are extremely soft and breathable, as the ink is absorbed into the fibers. DTF prints sit on top of the garment, so they feel slightly thicker, although modern powders have improved the hand feel significantly. If you prioritize projects softly, DTG printing has a slight edge.

6. Longevity

DTF prints are very durable and last longer, often with excellent resistance to washing and wear.

DTG prints are durable as well, especially when properly cured and treated, but repeated washes on dark or blended fabrics can sometimes lead to fading if not handled carefully.

7. Cost & Efficiency

DTG printers can be more expensive upfront, and ink costs tend to be higher, particularly for full-color designs.

In contrast, DTF tends to have lower production costs per garment and allows for batch printing, which is more cost-effective for medium to large runs. At LOGEQI, the printing cost of our personalized DTF T-shirts is $3 per shirt.

Learn more: 8 Best Methods for Printing T-Shirts 2026

8. Batch Size Suitability

DTG is ideal for small orders or one-offs, as it prints directly onto garments with minimal setup. DTF is better for batch production, since multiple films can be printed and pressed in succession.

9. Ease of Scaling Production

DTF offers greater scalability, as you can prepare designs in advance and apply them as needed. DTG requires direct printing onto each garment, which can slow down large-scale operations.

10. Versatility

DTF takes the win in garment versatility, performing well across different fabrics, colors, and textures. It can be applied to a wide range of garments, including t-shirts, hoodies, hats, tote bags, workwear, and even performance fabrics made from polyester or nylon.

DTG is excellent for soft cottons and small, highly detailed prints, but less flexible overall.

11. Use Cases

DTG is perfect for one-off or personalized pieces, such as custom t-shirts, gifts, or limited designs, thanks to its soft feel and detailed print quality. IT’s also perfect for small businesses or designs requiring photorealism.

DTF is ideal for batch production, varied fabrics, dark garments, and vibrant, durable prints.

Common Misconceptions

Despite their popularity, both DTG and DTF printing have their share of misconceptions.

-

DTG Can’t Handle Dark Shirts

A common belief is that DTG can’t print well on dark garments. While it’s true that light-colored DTG prints are easier, pre-treatment allows DTG to produce bright, vibrant designs on dark fabrics, proving this myth wrong.

-

DTF Is Inferior

Some assume DTF is a “lower-quality” option. In reality, DTF offers excellent durability, color vibrancy, and versatility. While the feel may be slightly different, its performance on varied fabrics often surpasses DTG in practical applications.

-

One Method Fits All

Finally, no single method is perfect for every project. Choosing the right printing methods depends on garment type, design complexity, batch size, and budget. Understanding both options through our blogs, we’re sure you can make smarter decisions for your needs.

So, DTG or DTF, Which is Better?

So, which printing method should you choose?

-

For small runs or detailed, photorealistic designs: DTG is ideal. It produces soft, breathable prints with incredible detail.

-

For larger batches, multiple fabrics, and vibrant colors on dark garments: DTF is the better option. Its durability, scalability, and versatility make it perfect for businesses looking to produce consistently high-quality prints across a range of apparel types.

Many apparel printers now use a combination of both technologies. Having DTG for specialty, custom orders, and DTF for batch or versatile printing allows businesses to handle virtually any project efficiently and effectively.

The truth is, neither DTG nor DTF is universally “better”. The right choice depends on what you’re printing and how you plan to use it.

If you’re creating one-off or personalized designs, working with cotton garments, or need photo-quality detail and a soft, breathable feel, DTG printing is the better option. It’s ideal for custom t-shirts, gifts, small brands, and designs where comfort and fine detail matter most.

On the other hand, if you’re producing larger batches, printing on multiple fabric types, or need bright, durable prints on dark garments, DTF printing stands out. Its versatility, long-lasting results, and cost efficiency make it a strong choice for scaling production and offering a wider range of apparel. By the way, DTF also works very well for single custom pieces, like a streetwear personalized graphic T-shirt.

In short, DTG excels in detail and softness, while DTF wins in durability, versatility, and efficiency.

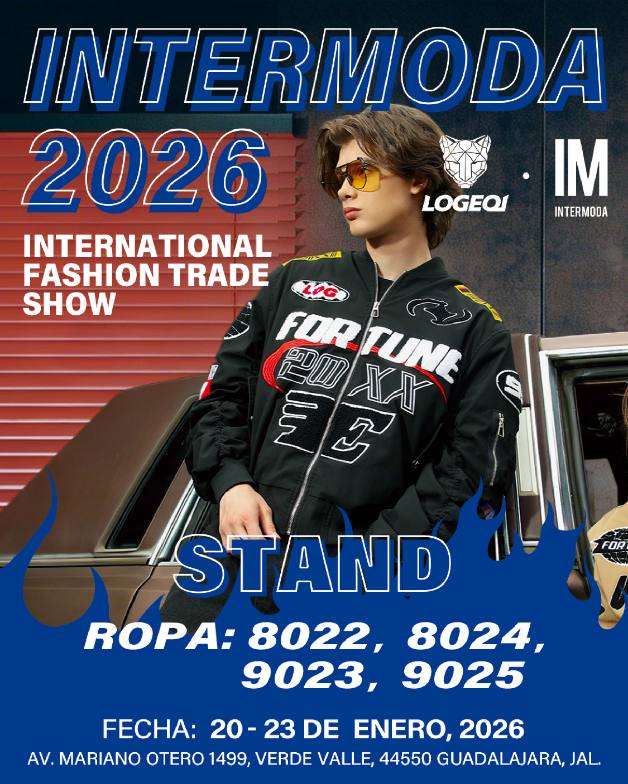

LOGEQI Personalized DTF Men’s Streetwear T-shirts

LOGEQI’s personalized DTF men’s streetwear T-shirts are perfect for custom gifts, fashion-forward individuals, small streetwear labels, and event merchandise. Our DTF T-shirts deliver vibrant colors that stand out on both light and dark fabrics.

Thanks to advanced DTF printing, each of our streetwear designs is durable, flexible, and resistant to fading after repeated washes. Whether you’re creating a one-of-a-kind piece or launching a limited drop, LOGEQI personalized DTF T-shirts offer versatility, strong visual impact, and reliable performance.

Looking for a special gift for him or unique streetwear pieces for yourself? Explore our personalized T-shirts collection to find truly standout designs.

Want to turn your artwork into reality or produce a small batch of unique streetwear for your brand? Contact us at service@logeqi.com or WhatsApp +86 18102839427.